Development of Custom Machinery

Custom-built systems that save money and increase your output

Custom machines for every industry, in any size

In the last 4 years, we have built unique components, machines and complete systems for over 100 customers. These individual developments make complex production processes simple, make tedious tasks faster and make dangerous work safer.

Custom Systems

We develop special systems that exactly match your needs, from the requirement analysis to the conception, manufacture, installation and ongoing maintenance.

Repair & Maintenance

We also take care of existing machines and special designs reliably. We keep your machines running, repair them when necessary and can also certify them according to a variety of standards.

Refurbishments & Upgrades

Save costs and reduce risk by replacing outdated machines and parts of all kinds with modern solutions. Let us bring your machines up to date at a minimal cost!

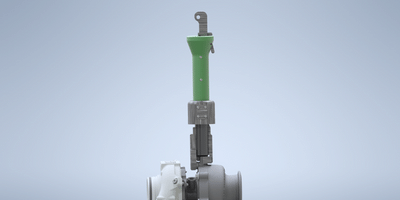

Process-Filtration

We advise, procure, configure and install completely customized filter systems – or simply choose the right standard solution for you!

3D Printing

We can convert ideas and 3D diagrams into finished prototypes within days using the latest 3D printers. We can also print special components in large numbers if necessary.

Custom Systems

We develop special systems that exactly match your needs, from the requirement analysis to the conception, manufacture, installation and ongoing maintenance.

Repair & Maintenance

We also take care of existing machines and special designs reliably. We keep your machines running, repair them when necessary and can also certify them according to a variety of standards.

Refurbishments & Upgrades

Save costs and reduce risk by replacing outdated machines and parts of all kinds with modern solutions. Let us bring your machines up to date at a minimal cost!

Process-Filtration

We advise, procure, configure and install completely customized filter systems – or simply choose the right standard solution for you!

3D Printing

We can convert ideas and 3D diagrams into finished prototypes within days using the latest 3D printers. We can also print special components in large numbers if necessary.

Typical industries for custom machinery:

For Car Factories

With our experience, we help you optimize serial processes, lifting processes, the design of assembly systems and many other processes.

For Cleaning Processes

We develop efficient solutions for your cleaning processes – from individual tools for the process to fully automated cleaning systems.

For Industrial Production

We increase your output with optimized series processes, screw and adhesive processes and fully automated systems for various industries.

Sample projects:

Fully automated production facility

For an error-prone production process in the photovoltaic field, we have developed and certified a facility that automates the entire process – faster, safer and error-free.

Two production processes can run in parallel and can be loaded and unloaded independently of each other.

The process includes plasma cleaning of surfaces, glue application and screwing of individual parts.

Transport system for hardening furnace

A 60-year-old furnace had to be renewed for a rolling/ball-bearing manufacturer. With detailed 3D scans, we first analyzed the entire facility, then made specific interventions to develop the transport system without having to replace the entire facility.

As a result, the facility was not only modernized but also safety-certified and future-proofed.

“Impossible” component

As part of a nozzle, this component was designed by us and produced with carbon fiber-reinforced polycarbonate in 3D printers.

With regular manufacturing methods, producing this element would not have been possible.